CHECK YOUR ELIGIBILITY

Pre-rinse spray valves - the unsung hero of the commercial kitchen

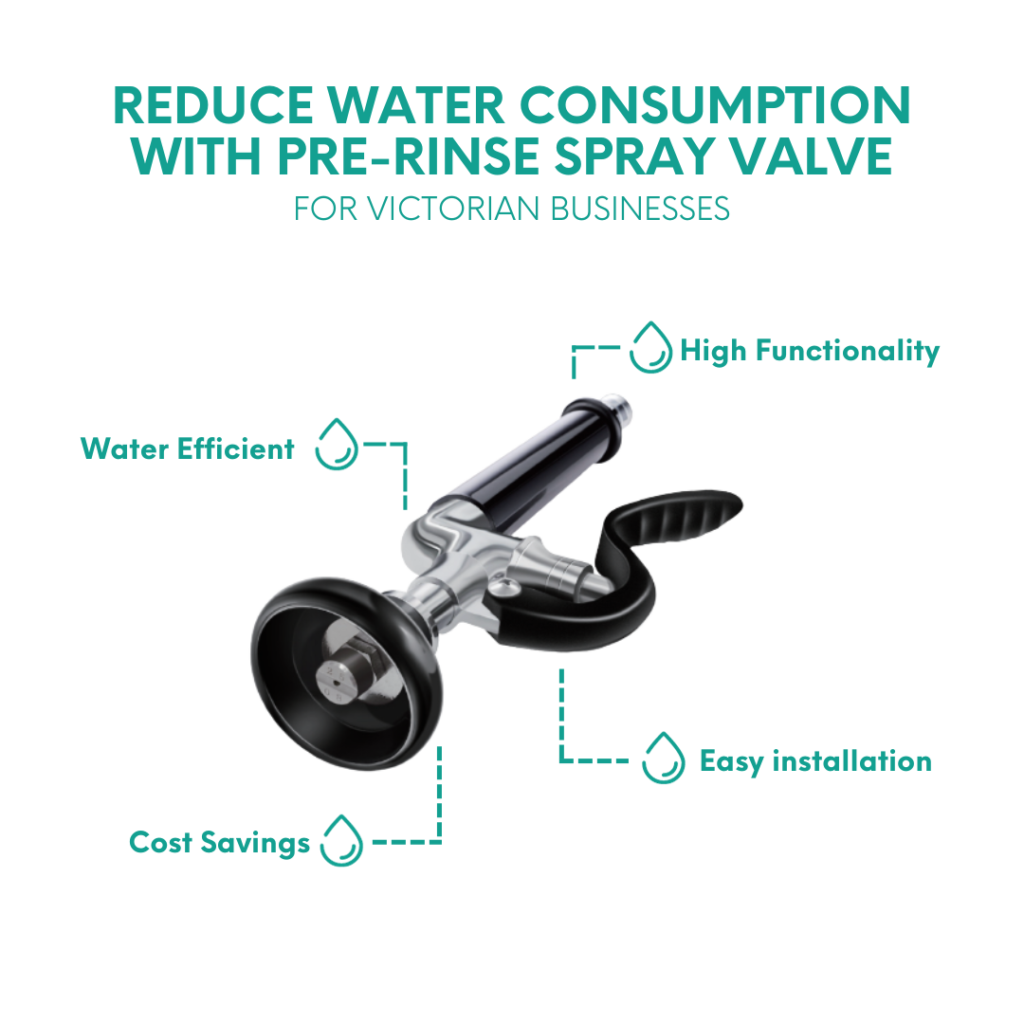

If you’re running a commercial kitchen, installing a water-efficient pre-rinse spray valve will reduce water and energy bills, and help the environment.

Water use in older Pre-rinse spray valves is typically between 10 and 15 litres per minute. They are usually fitted with a shower-type spray nozzle that relies on water volume for its cleaning action.

New WELS 6-star rated Pre-rinse spray valves use only 4 -6 litres per minute with added cleaning efficiency, performing the same tasks, using less water, in less time.

Pre-rinse spray valves generally deliver water at between 40-60oC, meaning energy savings of exchanging a valve delivering hot water from a gas system would be around 10.6GJ/yr per valve exchanged.

• cleans food off dishes faster and easier.

• saves up to two-thirds of water used by older models.

• reduces your water bill.

• uses less hot water, reducing your energy bill.

A simple yet impactful change is upgrading to a water-efficient Pre-rinse spray valve to reduce costs.

Replacing a Pre-rinse spray valve in your commercial kitchen can save between $160 – $352 per year and reduce your water cost by around $95 per year and energy costs by around $73 per year (for natural gas) or $256 per year (for electricity).

Over a year, this can save you thousands of litres of water usage and, therefore, hundreds of dollars on utilities.

Pre-rinse Spray ValvePre-rinse Spray Valve

In the restaurant industry, water consumption is significant. It’s used in serving customers, powering ice machines, operating dishwashers, and flowing through sinks. A simple yet impactful change is upgrading to a water-efficient pre-rinse spray valve to reduce costs.

The pre-rinse spray valve plays a crucial role in commercial kitchens. It removes leftover food and debris from dishes before they enter the dishwasher. Switching from an outdated valve to a more efficient model significantly lowers water usage, leading to cost savings.